Brüel Acoustics

Anecho Test Facilities: 62BA and

62BB

Brüel Acoustics have developed two modular Anecho Test Rooms for

industrial research, acoustical measurements and

calibration.

The test chamber is a light construction named

type 62BA (modul 40 cm) and the system for larger rooms

type 62BB (modul 60 cm).

The modular system makes use of a

1imited number of standard elements which can be connected together and form

more than 100 rooms with different lenght, weight and height.

On a given

space all dimensions can be made by choosing the nearest number of moduls.

The price for the rooms are proportional to the element units.

Wedges are normally build of the same material both at the bottom and the

top. In the loudspeaker analogy this correspond to a linear cone in front of the

driver.

Consequently the Cremer room is much better at high

frequencies than a Wedge room of the same size.

At mid frequencies

the two types are equel, and at low frequencies the Wedge type is normally

slightly better.

From an economical point of view it can be said that a

Wedge room contains more absorbing material than a Cremer room, but a Cremer

room requires more sophisticated work which means higher labour cost.

At

B&K we used only Cremer type rooms because it is very important that

the room is good at higher frequencies up to 15 kHz.

The lower

frequencies below 300 Hz are not so important as the wavelength is large so that

other methods can be used.

With frequencies over 3 kHz a Wedge room will

always give some uncontrollable fase shifts because the Wedges

have large plane surfaces whereas the Cremer rooms have an acoustical jungle.

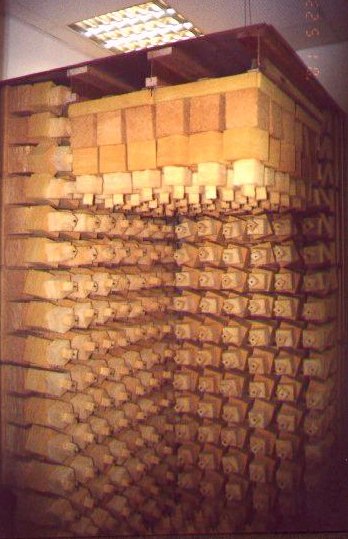

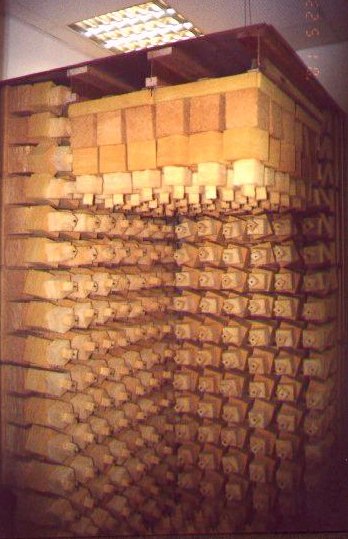

Construction:

Both Cremer

types are built of tubes where no plane surfaces exist.

Consequently

all reflections are minimized in all directions.

Most of the

supporting structure is imbedded in the absorbing material.

Type 62BA have a modul length of 40 cm and also a wall

thickness of 40 cm. Supporting tubes have a diameter of 10 mm.

This room

works very accurately from 350 Hz to 25 kHz depending of the

size.

Type 62BB has a modul length and a wall thickness of

60 cm and is intented for bigger rooms and working frequencies from 200

Hz to 20 kHz.

Both rooms should be erected on a plane smooth surface

e.g. reinforced concrete or very hard wood.

A concrete slab are ideal and can conveniently be supported by steel springs for vibration isolation.

Floors:

Both types can work

with and without an absorbing floor and therefore satisfy all standards in force

today.

The absorbing floor consists of easy removable units.

It takes

only a few minutes to remove the floor.

It is therefore important that the

base reflects the sound and is plane.

Doors:

The door can consist of

one or two units in width and two, three, or four units in height.

The door

itself consists of units which like the floor fits in the normal wall units.

The door is rolling out perpendicular to the wall.

When it is out, it is

rolled parallel sidewards.

This movement is done on rails with roller

bearings.

How much space is needed?:

The rooms can be erected from the "inside" and therefore the

space required is only 5 to 10 cm space between testroom and fixed building.

But remember the test rooms can only be delivered in units of 60 or 40 cm.

The space from the wall where the door is installed has to be the wall

tickness (60 or 40 cm) + 10 cm.

This small space is minimum.

The

erection is faster and easier if more space is available.

Ventilation:

Air should not be

blown into the test room.

Heavy draught will break some of the glass fibres

and produce dust. But the air around the room can be airconditioned without

problems.

Lisht and Electric Cables are easily installed in a Cremer room as there is a

lot of space in the absorbing walls.

It is very easy to change the cables.